In the evolving world of fabric printing, Direct to Film (DTF) printing is emerging as a

powerful alternative to traditional printing methods. For businesses and designers in

Kuala Lumpur exploring the best printing options, understanding how DTF stands

against conventional techniques is crucial. This post compares DTF printing with

traditional methods like screen printing and DTG (Direct to Garment), highlighting

their differences in terms of quality, efficiency, cost, and versatility.

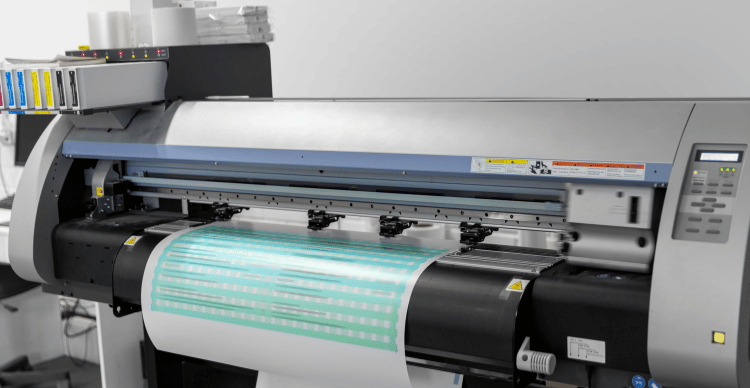

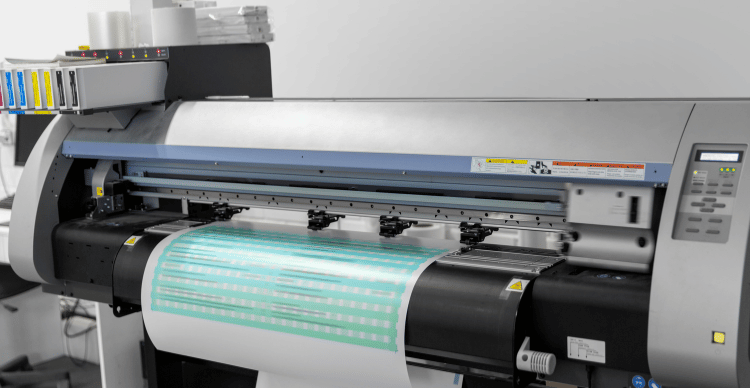

Understanding DTF Printing

DTF printing involves printing a design onto a special film, which is then transferred

onto fabric using heat. This technology allows for vibrant, high-quality prints that are

durable and flexible. It is especially beneficial for designs that require high detail and

color fidelity.

Screen Printing

Screen printing, one of the oldest and most traditional methods, involves creating a

stencil (or screen) and using it to apply layers of ink on the printing surface. This

technique is best suited for high-volume orders as it requires significant setup.

Direct to Garment (DTG)

DTG printing involves printing directly onto the fabric using inkjet technology. It is

ideal for detailed and color-rich designs on small to medium batch sizes, but the

print’s durability can vary depending on the fabric and ink quality.

Comparison Criteria

- Quality and Durability

● DTF: Produces vibrant and precise color prints that are highly durable

and resistant to washing.

● Screen Printing: Offers good color saturation and durability but can be

limited in detail and color gradients.

● DTG: High detail and good color fidelity but may fade faster than the

other methods without proper care. - Efficiency and Speed

● DTF: Relatively quick once the initial setup is done, suitable for both

small and large batches.

● Screen Printing: Efficient for large orders but the setup process can be

lengthy and complex.

● DTG: Quick setup, ideal for small runs, though slower per piece

compared to screen printing.

- Cost

● DTF: Cost-effective for small to medium runs; setup costs are lower

than screen printing but higher than DTG.

● Screen Printing: High initial setup costs, making it less economical for

small runs but cost-effective at large volumes.

● DTG: Lower setup costs, cost per item can be high, making it less

suitable for large batches. - Versatility

● DTF: Can be used on a variety of fabrics and colours, including dark

textiles.

● Screen Printing: Best on cotton and light-coloured fabrics; using on

dark colours requires additional layers.

● DTG: Works well on cotton and light colours; performance on dark

colours and synthetic fabrics can vary.

Conclusion

Choosing the right printing technology depends largely on your specific needs. DTF

printing offers a versatile and cost-effective solution for both small and large orders,

providing durability and colour accuracy that can match traditional techniques. For

businesses in Kuala Lumpur, investing in SP Tech for DTF printing needs means

accessing state-of-the-art technology capable of delivering superior results across

various fabric types. Whether you’re looking to produce vibrant fashion pieces,

promotional apparel, or custom merchandise, DTF could be the ideal choice,

combining the best aspects of traditional techniques with the innovations of modern

technology.