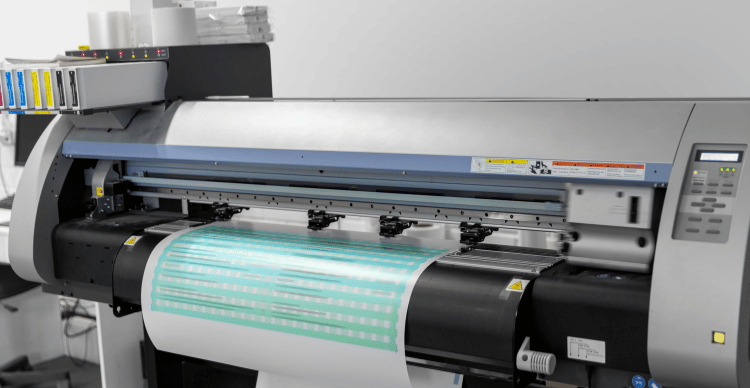

Direct to Film (DTF) printing is a game-changer in the textile industry, offering

versatility, efficiency, and high-quality prints. As this technology becomes more

popular in Kuala Lumpur, choosing the right DTF printer is crucial for businesses

looking to enhance their printing capabilities. This guide will help you identify the key

factors to consider when selecting a DTF printer that meets your business needs.

- Print Quality and Resolution

The quality of the prints produced by a DTF printer is paramount. High resolution is

essential for achieving sharp, detailed images, especially when working with

complex designs or fine text. Look for printers that offer high DPI (dots per inch)

settings and advanced colour management capabilities. This ensures that the prints

not only look vibrant but also maintain colour accuracy and consistency. - Printer Speed and Productivity

Speed is a critical factor, particularly for businesses with high-volume printing needs.

Assess the printer’s speed in terms of square metres per hour to understand how

much output it can handle. A faster printer can significantly increase your production

capacity, reducing turnaround times and allowing you to fulfil more orders. - Media Compatibility

DTF printers should be compatible with a wide range of film and powder types. This

flexibility allows you to experiment with different materials and find the ones that

best suit your specific product offerings. Check if the printer can handle various film

thicknesses and powder applications, as this will impact the final product’s quality

and durability. - Ease of Use and Maintenance

The usability of a DTF printer is crucial for smooth operations. Look for printers with

user-friendly interfaces, straightforward setup processes, and minimal maintenance

requirements. Additionally, consider the level of technical support and training

provided by the manufacturer. Easy access to customer service and maintenance

support can prevent extended downtime and ensure continuous production. - Cost Efficiency

Evaluate the total cost of ownership, including initial investment, ink costs, film, and

powder expenses. While a cheaper printer might seem appealing initially, the

long-term costs due to higher consumable prices or frequent repairs can add up. It’s

important to balance upfront costs with operational expenses to find a printer that

provides the best value for money.

- Software and Connectivity

Modern DTF printers come equipped with sophisticated software that offers

enhanced functionality like detailed image editing and efficient workflow

management. Additionally, connectivity options such as USB, Ethernet, and Wi-Fi can

streamline operations and integrate seamlessly into your existing workflow. Ensure

the software is intuitive and supports your production process effectively. - After-Sales Service and Warranty

Reliable after-sales service and a comprehensive warranty are essential for

safeguarding your investment. Check the warranty length and what it covers.

Consider manufacturers like SP Tech that provide robust support and service

agreements to help maintain your printer in optimal condition. - Reviews and Recommendations

Finally, seek feedback from current users. Online reviews, testimonials, and forums

can provide insights into the printer’s performance and reliability. Networking with

industry peers at events or through online platforms can also offer valuable firsthand

information that may influence your decision.

Conclusion

Choosing the right DTF printer involves careful consideration of your business’s

specific needs and the printer’s features. By taking into account factors like print

quality, speed, compatibility, and cost efficiency, you can select a DTF printer that not

only meets but exceeds your expectations, enhancing both productivity and product

quality. SP Tech offers expertise and support in selecting the perfect DTF printer for

your business, ensuring you get the most out of this innovative technology.